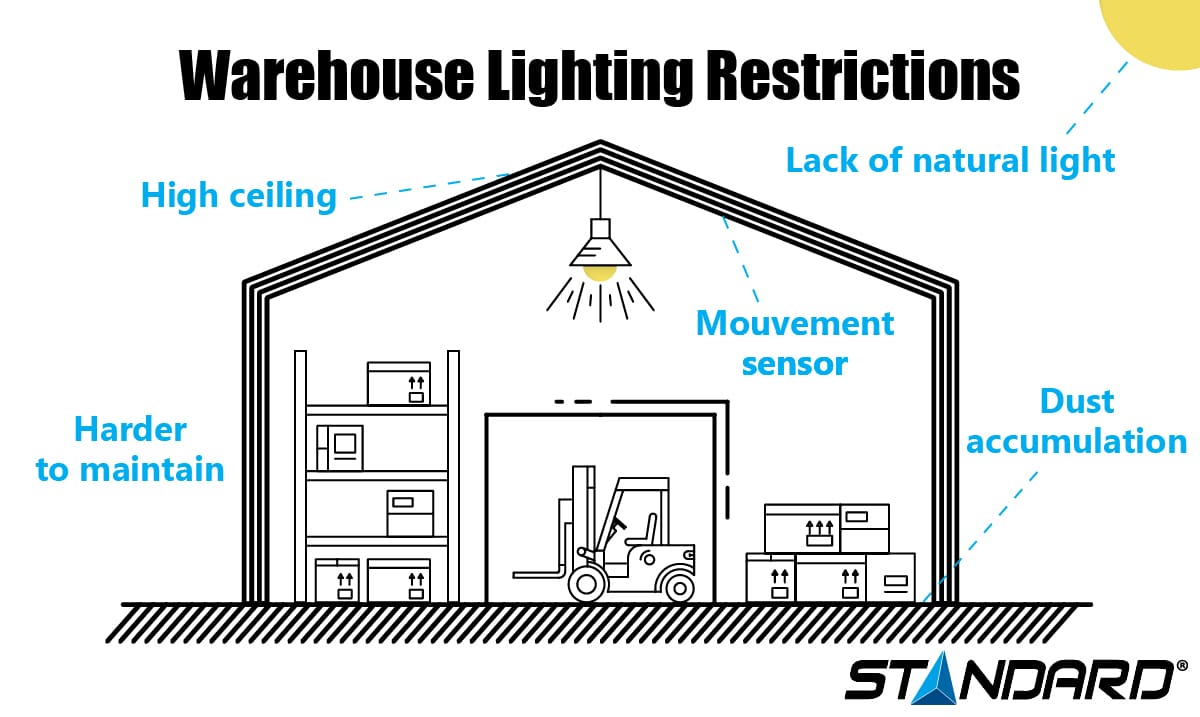

Warehouses and industrial buildings exhibit unique characteristics. These include: few windows, high ceilings, elevated shelving, and large floor surfaces. All these factors require a very specific warehouse lighting system that adapts and conforms to the following needs:

- Reduce maintenance costs

- Refresh the operational efficiency of a given space

- Increase work productivity

- Improve workers’ safety as well as their working conditions

- Respect the environment

LED Lighting – Saving on Maintenance Costs

LED fixtures have become the buzz tool in the lighting industry. They are very well suited to warehouse lighting. LED high bay luminaires offer top performance as well as exceptional quality and versatility. They utilize 60% less energy than traditional fluorescent and HID lighting systems. Moreover, they are designed to reduce your energy consumption costs while providing your warehouse space with regular, contemporary lighting. The benefits of LED lighting include, amongst others, a longer life span. Ceiling height and the considerable amount of fixtures in this type of space result in significant maintenance costs. Changing a simple light bulb often involves an elaborate process, such as the use of a forklift that can be quite costly in both time and dollars spent. LED maintenance and energy consumption are modest. They represent major advantages in large spaces with high ceilings. Finally, an LED lighting system significantly lowers heat output. Therefore, it is not necessary to air-condition a warehouse to counteract the heat produced by the lighting fixtures since LED lighting minimizes the cost of air conditioning. We call this “ the cross-effect of lighting conversion” and it is an essential feature in cost-saving calculations. Do note, however, that the initial purchase of a LED lighting system is a costlier investment than the purchase of traditional lighting. When considering an overhaul of your warehouse lighting, you may also examine fluorescent lighting options.T5HO Fluorescent Luminaries: A Budget-Conscious Solution

Warehouse facilities can also benefit from the use of T5HO fluorescent luminaires instead of LED luminaires. These fixtures contain several T5HO tubes as well as a reflector that will angle the light flux toward the workspace to ensure optimal visibility. Additionally, the cost of installing these luminaires is modest and the lighting quality is more than adequate.Suitable Lighting for a Warehouse

Warehouses with high ceilings demand a specific lighting system in order to make sure the space is sufficiently bright to work in. Our LED high bay luminaires are designed for 18- to 60-inch mounting heights and supply up to 95% of lumens for up to 60,000 hours. They are well suited to high ceilings (varying from 10 to 60 feet) and ensure superior quality, high-performance lighting. They provide constant brightness with both direct and indirect lighting. Many high ceiling lighting solutions offer additional features that are perfect for warehouse installations such as preventing loss of light due to the accumulation of dust, protecting luminaries against damage and facilitating their maintenance.Dimming Solutions

The installation of a luminous flux adjustor can also be a convenient option for your warehouse lighting. If it receives a fair stream of natural light in some areas, for instance, it might be appropriate to reduce the intensity of your lighting system in those particular zones. This would significantly minimize your energy costs.Motion Sensors Help with Lighting Management

In many warehouses, lighting control components are often difficult to reach or may be too far to access. Motion sensors serve to coordinate the diffusion of light based on occupancy in various areas of the warehouse. In spaces where there is no activity, there is no need to keep lights on at all times. Using motion sensors, warehouse owners can keep their energy costs down.Conclusion

Several solutions are available to light a warehouse both properly and efficiently. A system that is well adapted to the space will serve to improve work habits and the well-being of employees while reducing maintenance fees and the luminaire costs.